20X-70-14160TL Komatsu PC100TL 20X-70-12130 Bucket Tips Tooth Point

PartNo. 20X-70-14160TL 20X-70-12130 Komatsu PC100TL,PC70, PC71, PC100,PC130-7,PC160-7 Bucket Tips Tooth Point

Weight 2.2kgs

Brand Name Custom Logo

Replacement Brand Komatsu /shantui

Material High spec alloy steel

Color Yellow, black, red, green or as your required

Process Investment casting / Lost wax casting / sand casting /forged / forging

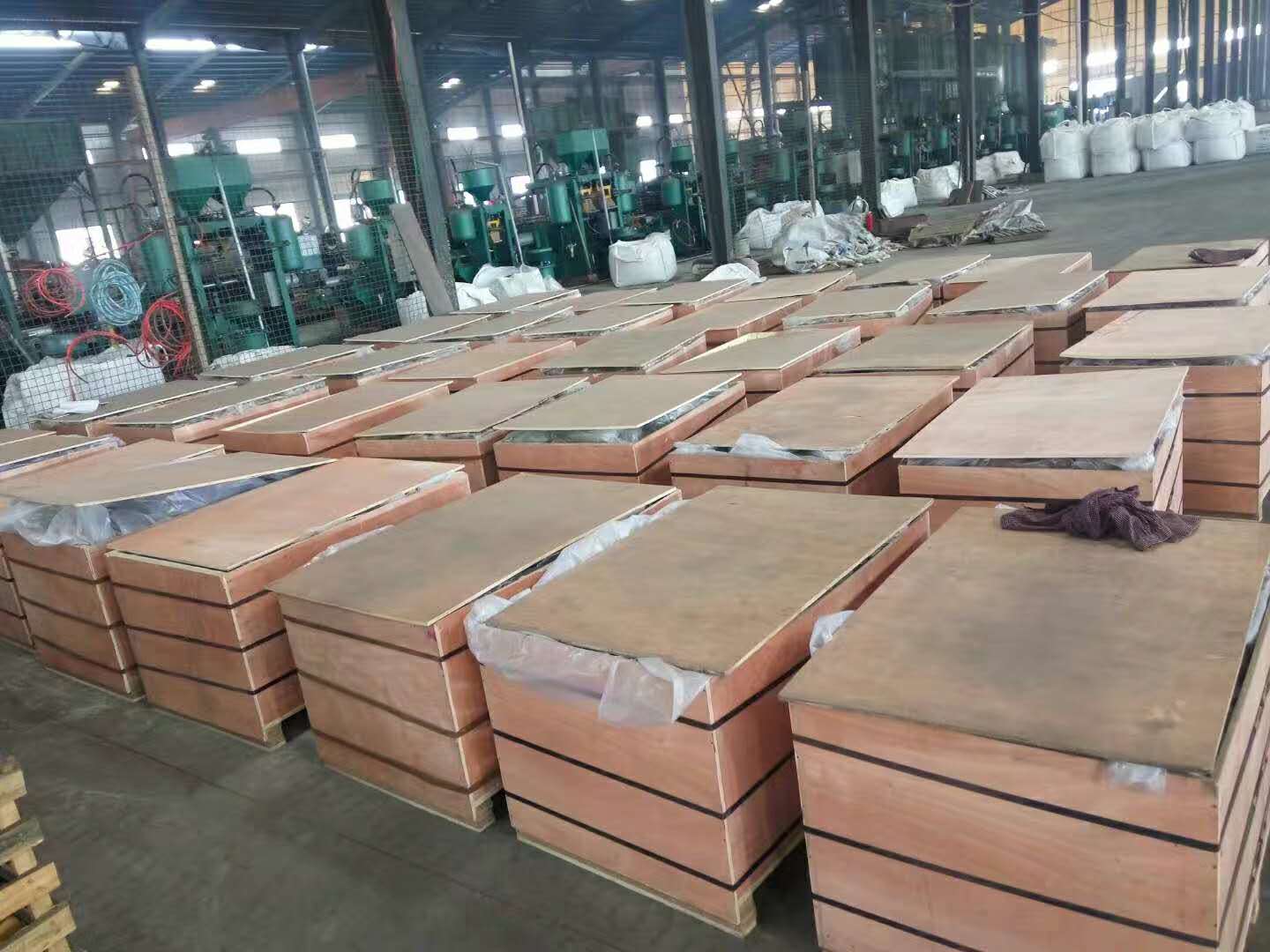

Packing Normal plywood case about 2tons per case

Tensile strength >1400Rm-N/mm

shock >20J

Hardness 48-52HRC

Certification 1so9001:2008

Samples Offer sample with free of charge, but freight collect

Place of OriginGuangZhou, china (Mainland)

Product Description

Komatsu Bucket Tooth

Komatsu Bucket Tooth, Komatsu Tooth System, Replacement Komatsu style Teeth, Bucket and Ripper Tips Point For LOADERS, EXCAVATORS, BULLDOZERS, BACKHOES, MOTORGRADERS AND SCRAPERS

Model

Komatsu Excavator & Loader Bucket Tooth and Ripper Tips by Machine: WA180, WA250 WA320 WA380 WA400 WA420 WA450 WA470 WA500 WA600 WA700, PC60 PC100 PC120 PC200 PC210 PC220 PC300 PC400 PC650 PC750 PC1000 …

Komatsu bucket and ripper teeth with extra wear material and longer service life, excellent penetration and auto sharpening for heavy duty applications. Komatsu Bucket Teeth have a one piece, horizontal pin and larger holes to assist with stability, durability and ease of installation whilst on site.

XHGET customers rely on Komatsu Bucket Tooth for the most demanding mining, forestry, construction and other groundbreaking applications on earth.

Fix them today, with the worlds safest, most trusted, hammerless Bucket Tooth System China Supplier & Factory – XHGET ! Guaranteed longer wear life & no loss of Teeth ! we stock the largest range of Bucket Tips in China, with various fitment styles & systems for all makes & models of Excavators & Loaders.

Use the search panel below to find the ultimate Bucket Teeth & Adapters for your machine. Can’t find a part? Call our experts on +86 187 0795 5350 or Send a Email to discuss your needs.

Disclaimer: All parts listed on this site are aftermarket replacement parts and are not manufactured by the original machinery manufacturers.

Komatsu Bucket Teeth

Machine No Part No. Weight(KG)

PC60 PC60 PC60 1.7

PC100 PC100 1.9

PC120-3 PC120-3 202-70-12130 3.9

PC200 PC200 205-70-19570 3.9

PC200 PC200 205-70-19570 5.6

PC300 PC300 207-70-14151 5.8

PC300 PC300 207-70-14151 6.3

PC300 PC300 207-70-14151 7.1

PC400 PC400 208-70-14152 10.5

PC400 PC400 208-70-14270 14.5

PC500 PC500 17.0

SYL Tooth

Machine No Part No. Weight(KG)

PC120-7 PC120-7 3.6

PC200-E 205-70-19570SYL 4.2

PC300 207-70-14151SYL 6.3

Rock chisel

Machine No Part No.weight(kG)

PC200-ZPC200-Z205-70-19570RC4.8

PC200-H PC200 205-70-19570RC 5.5

PC60RC PC60 RC 1.9

PC100RC 202-70-12130RC 23

PC120-3 PC120-3 RC 3.9

PC200 205-70-19570RC 4.6

PC200 205-70-19570RC51

PC300 207-70-14151RC 8.2

PC300 207-70-14151RC 8.4

PC300/PC360 207-70-14151RC 91

PC400 208-70-14152RC 14.3

PC400 208-70-14152RC 15.8

PC650 209-70-54210RC 31.2

PC1250 21N-72-14290 52.0

Heavy Duty Long RC

PC200RC 205-70-19570RC 6.4

PC300RC 207-70-14151RC 9.6

Rock chisel

Machine No Part No. weight(kG)

PC60 PC60RC 1.6

PC100 202-70-12130RC 21

PC200 205-70-19570RC 5.4

PC300 207-70-14280RC 8.5

PC400 208-70-14152RC 14.0

PC200 205-70-19570RC 4.8

PC300 207-70-14151RC 7.9

PC400 208-70-14152RC 13.2

Tiger Tooth

Machine No Part No. weight(kG)

PC200TL205-70-19570TL6.4

PC200TL205-70-19570TL5.3

PC300TL207-70-14280TL8.5

PC300TL207-70-14280TL8.7

PC400TL208-70-14152TL13.7

PC400TL208-70-14152TL15.20

PC650TL209-70-54210TL22.9

Ripper Tooth (scarifier)

Machine No Part No. weight(kG)

D31 D3IPL113-78-21140 4.0

D40“D40/D45

D40/D41

D50/D53-16

D50/D53-17

D66S"131-78-31190 10.5

D60"D60/D45-7

D60/D65-8

D65-12 D75A-1

D75S-3 D75S-5

D85E-SS-2A"141-78-11253 12.0

D60"D60/D45-7

D60/D65-8

D65-12 D75A-1

D75S-3 D75S-5

D85E-SS-2A"141-78-11254 12.5

D85/155 D85/0135/0155 175-78-31230 15.2

D85 175-78-31230 13.8

D85TL175-78-31230 14.5

D275 D275/355/455 195-78-2133115.7

D275 D275 195-78-21331 17

D275 D275/0355/0455 195-78-29140 21.5

D375 D375 195-78-71320 25.2

D475 D475 198-78-21340 40.2

Tiger

D85TL175-78-31230 TL12.0

D90TL(4T5501)4T5501TL18.8

Loader Teeth

Machine No Part No.weiaht(k

D66 D66/PC300 207-70-14151

WA70 WA70-1415-847-1110

WA100 WA100-1.WA120-1.WA150-1201-70-24140

WA180(PC100)WA180-1,WA200-1WA250-120X-70-14160 1.7

WA300(PC120-3)WA300-1.WA320-1202-70-12130/419-71-H2310 3.8

WA380 WA350/380/400/420/450/470 423-847-1140 8.7

WA500/600 WA500/600 426-847-1110 11.7

WA700 WA700 427-70-13731 30.2

WA800 WA800 427-842-1120/427-70-13780 51.5

Loader Monoblock Teeth(2 holes)

WA20 105-70-22211

WA500 425-70-13212

D50s-16/D53s-16/D57s-s/D75S-1135-70-34110 12.0

D955 155-70-14112

D155S-1178-70-14110

WA300 35mm WA300/WA320 419-70-13113 12.7

WA300 WA300-470 419-70-13114 12.8

Loader Monoblock Teeth (3 holes)

Machine No Part No. weight(kG)

WA40 20T-70-13130

WA60 113-70-22140

WA180(30mm)WA180 418-70-13150/13151 6.5

WA320 WA300-1-2-3,WA320-1-2-3-4 419-70-13163 13.5

WA380(38MM)WA380M 423-70-13114 16.7

WA450 WA350/400/420/450 423-70-13113 20.5

D20/215-5/D21Q-5 103-70-22140

D31s-17,18 113-70-22140

D310-17,18 125-70-21810

D505-15,D555-3,D53S-15135-70-13411

D60,D65S-7,8 145-70-19181

D665-1,D755-3,5145-70-44110/145-70-44181

Corner Tooth

Machine No Part No. weight(kG)

WA180(26mm)WA180 418-70-13160 9.4

WA180(26mm)WA180 418-70-13170 9.4

WA300(27mm)WA300419-70-1316414.2

WA300(27mm)WA300 419-70-1317414.2

WA300 419-847-1131-27 10.0

WA300 419-847-1121-27 10.0

WA300 WA300-1-2-3,WA320-1-2-3-4 419-70-13160 14.2WA300 WA300-1-2-3,WA320-1-2-3-4 419-70-13170 14.2

WA380-40 WA380/450BL 423-70-13144 22.7

WA380-40 WA380/450BR 423-70-13154 22.7

WA500-40 WA500 423-847-1131 15.5

WA500-40 WA500 423-847-1121 15.5

Jiangxi Xinhang Precision Casting Co., LTD

Jiangxi Xinhang Precision Casting Co., Ltd. was founded in 2011, covering an area of over 120 mu and having more than 300 employees. It is located in Xinjie Industrial Park, the China Building Ceramics Industry Base, at the junction of Gao 'an City, Bajing, Xinjie and Ducheng Towns in Jiangxi Province.

The company was established with high standards and made its first investment in accordance with the management standards and ideas of modern enterprises. It is a modern enterprise that integrates design, casting and processing, and is strictly built in line with the national environmental protection standards. The company currently has two production lines for resin sand and precision casting wax molds, and is equipped with a machining center and multiple sets of high-precision mechanical processing equipment. With an annual production capacity of over 10,000 tons of construction machinery parts and various castings, the company conducts internal quality control in accordance with product quality standards that are stricter than those of ***, ensuring that the quality of all "Xinhang" products reaches the advanced domestic level

_20250805092253A003.jpg)

High toughness

The toughness is significantly enhanced compared with the common bucket teeth, and it is less likely to break during the impact process.

High wear resistance

Alloy steel bucket teeth are made of low-carbon alloy steel, and their wear resistance is four to five times that of common high manganese steel bucket teeth.

High hardness

Alloy steel bucket teeth have high hardness, penetrate the soil much faster than ordinary bucket teeth, and are more powerful than ordinary bucket teeth.

Beneficial

The high-quality products have significantly reduced the frequency of replacing the bucket teeth of the rotary drilling rig, saving the cost of the bucket teeth themselves and also lowering the labor cost of replacement.

Xinhang is one of the few manufacturers that simultaneously possess production lines for coated sand and wax film processes, with an annual output of over 10,000 tons. We provide OEM private label production for numerous brands, and our products are sold to over 20 countries. The factory has accumulated the development of various types (irregular shapes) and molds of different sizes, and can quickly deliver orders of different kinds and quantities. The delivery time for a 26-ton to 27-ton container is approximately 20 days.

Enterprise spirit: Integrity, Innovation, Professionalism

Corporate Mission: Lead customer needs, guide employees' ideals, and shoulder social responsibilities

Corporate Vision: Committed to building a reliable brand in the field of construction machinery parts

Core values: Innovation, Integrity, and Win-win

We offer 7* 24-hour technical support services. Integrate the productivity of the Internet and support drop shipping domestically. Xinhang strives to assist dealers in rapidly developing the market, aiming to enable customers to make money and also allow customers' customers to make money.

Related Products

B100, 20X-70-14151,20X-70-14160,20x-70-12130 Komatsu PC100 Standard Bucket Tips Tooth Point

Specification: PartNo.B100, 20X-70-14151,20X-70-14160,20x-70-12130,PC75,PC100-7,PC130-7,PC160-7 Weight 2kgs Brand Name Custom Logo Replacement Brand Komatsu /shantui Material High spec alloy steel Color Yellow, black, red, green or as your required Process Investment casting / Lost wax casting / sand casting /forged / forging Packing Normal plywood case about 2tons per case Tensile strength >1400Rm-N/mm shock >20J Hardness 48-52HRC Certification 1so9001:2008 Samples Offer sample with free of charge, but freight collect Place of OriginGuangZhou, china (Mainland)

20X-70-14151 Komatsu PC100 Bucket Side Pin Adapter

Specification: PartNo. 20X-70-14151 Komatsu PC100 Komatsu Bucket Side Pin Adapter(straight mouth) Adaptation PC70, PC71, PC100,PC130-7,PC160-7 Bucket Tips Tooth Point Weight 3kgs Brand Name Custom Logo Replacement Brand Komatsu /shantuiMaterial High spec alloy steel Color black or as your requiredProcess Investment casting / Lost wax casting / sand casting /forged / forging Packing Normal plywood case about 2tons per caseTensile strength >1400Rm-N/mm shock >20J Hardness 48-52HRC Certification 1so9001:2008 Samples Offer sample with free of charge, but freight collectPlace of OriginGuangZhou, china (Mainland)

20X-70-14160RC PC100RC 20X-70-12130 Komatsu Rock Chisel Bucket Teeth

Specification: PartNo. 20X-70-14160RC,20X-70-12130 Komatsu PC100RC,PC70, PC71, PC100,PC130-7,PC160-7 Bucket Tips Tooth Point Weight 2kgs Brand Name Custom Logo Replacement Brand Komatsu /shantui Material High spec alloy steel Color Yellow, black, red, green or as your required Process Investment casting / Lost wax casting / sand casting /forged / forging Packing Normal plywood case about 2tons per case Tensile strength >1400Rm-N/mm shock >20J Hardness 48-52HRC Certification 1so9001:2008 Samples Offer sample with free of charge, but freight collect Place of OriginGuangZhou, china (Mainland)

20X-70-00100 Komatsu Bucket Tooth Pins

Specification: PartNo.20X-70-00100 Komatsu Bucket Tooth Pins Adaptation 20X-70-14151 Komatsu PC100 Komatsu Bucket Side Pin Adapter PC56 PC60 PC70, PC71, PC100,PC130-7,PC160-7 PC200 PC300 PC400 Bucket Tips Tooth Point Komatsu series dedicated bucket gear pins/medium clamps Weight 0.3kgs Komatsu style pin for a 20X-70-14160 bucket tooth. Quality aftermarket G.E.T. (bucket teeth) for Caterpillar (CAT), JCB, Bobcat, Takeuchi, John Deere, Case, Komatsu, Kubota and many others including manufacturers such as ESCO, Hensley, H&L for all your backhoe, loader, skid steer, grader, scraper and excavator bucket tooth (teeth) needs.

201-70-24140RC PC60RC Komatsu Rock Chisel Bucket Teeth

Specification: PartNo. A60/201-70-24140 A60RC/201-70-24140RC PC60RC A60TL201-70-24140TL Weight 1.7kgs Brand Name Custom Logo Replacement Brand Komatsu /shantui Material High spec alloy steel Color Yellow, black, red, green or as your required Process Investment casting / Lost wax casting / sand casting /forged / forging Packing Normal plywood case about 2tons per case Tensile strength >1400Rm-N/mm shock >20J Hardness 48-52HRC Certification 1so9001:2008 Samples Offer sample with free of charge, but freight collect Place of OriginGuangZhou, china (Mainland)

201-70-24140 Komatsu PC60 Standard Bucket Tips Tooth Point

Specification: PartNo. A60/201-70-24140 A60RC/201-70-24140RC PC60RC A60TL201-70-24140TL Weight 1.7kgs Brand Name Custom Logo Replacement Brand Komatsu /shantui Material High spec alloy steel Color Yellow, black, red, green or as your required Process Investment casting / Lost wax casting / sand casting /forged / forging Packing Normal plywood case about 2tons per case Tensile strength >1400Rm-N/mm shock >20J Hardness 48-52HRC Certification 1so9001:2008 Samples Offer sample with free of charge, but freight collect Place of OriginGuangZhou, china (Mainland)